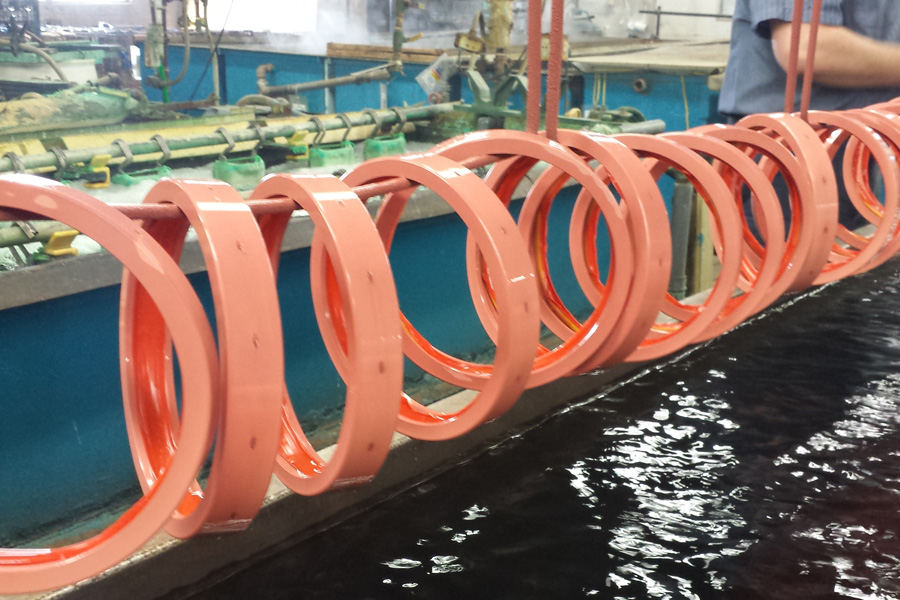

Copper has a reddish-orange metallic hue. Copper plating is essential is many plating operations as a strike and, to a decreasing extent, for thick deposits. Copper Plating is frequently used as an underplate due to its ability to adhere extremely well to a variety of different substrates. It can be used as an undercoat in situations where enhanced adhesion for additional coatings of other materials is desired. Copper is a particularly useful substance in numerous heating, industrial, and electrical applications due to its excellent thermal and conductive properties.

Benefits:

- Electrically Conductive

- Ductility – beneficial for metals that require flexibility; Won’t separate when bent

- Adhesion

- Corrosion Resistance

- Cost-Effective

- Great diffusion barrier

- Rebuild- Used to rebuild damaged or pitted surfaces

Copper Plating Specifications:

- AMS 2418 Rev. H

Abilities:

- Rack

- Barrel

- Size: Max (144” x 25” x 45”)